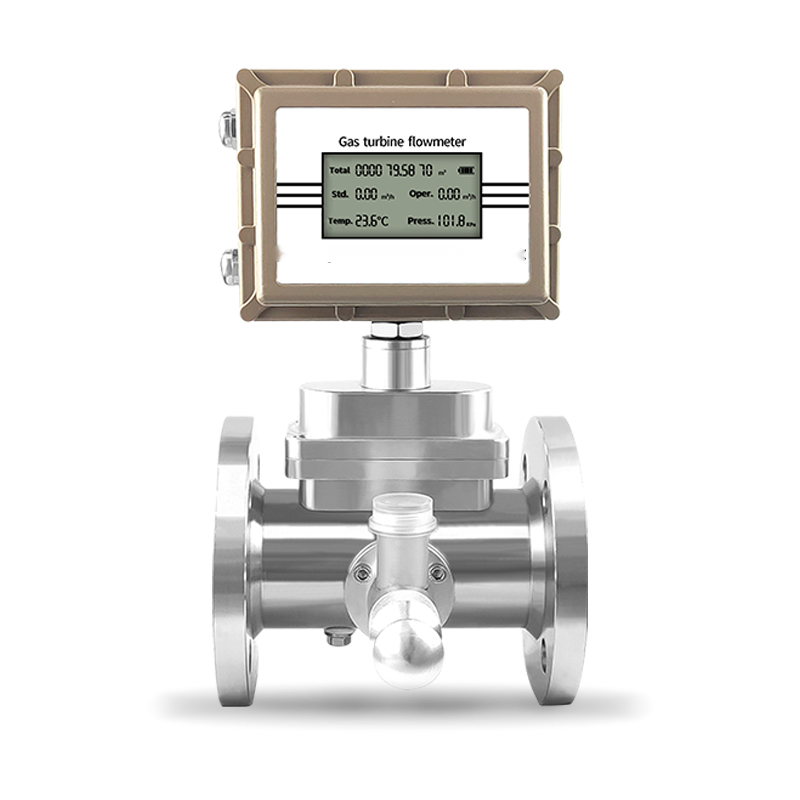

Flow Quantitative Control Box

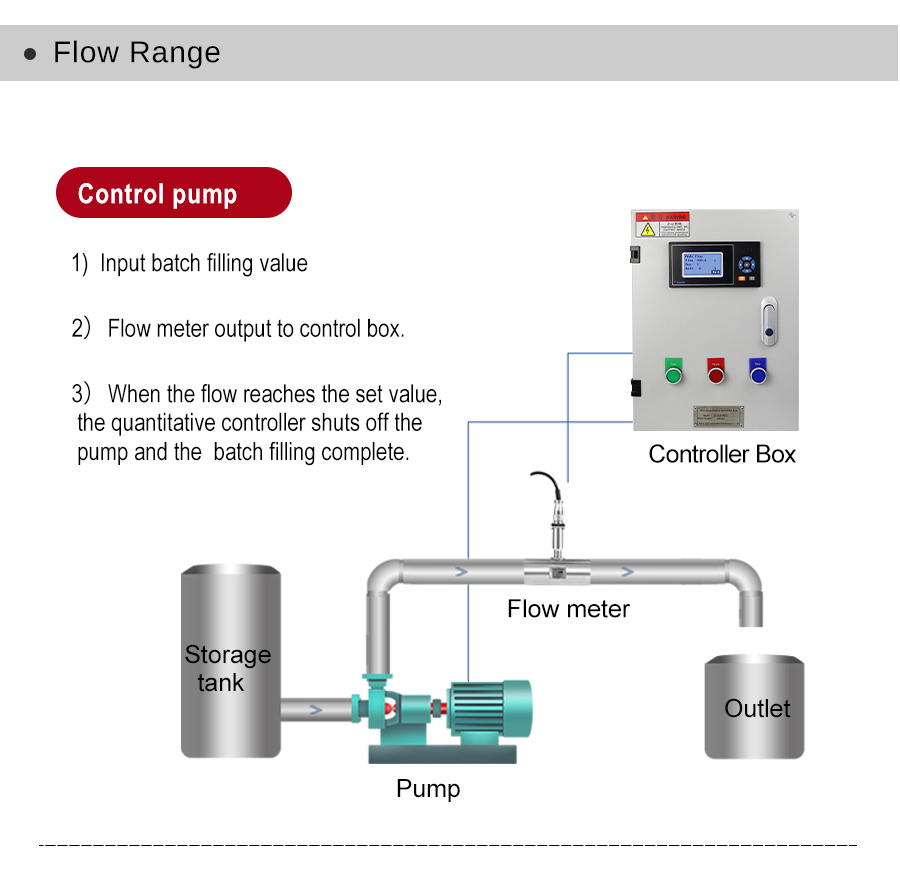

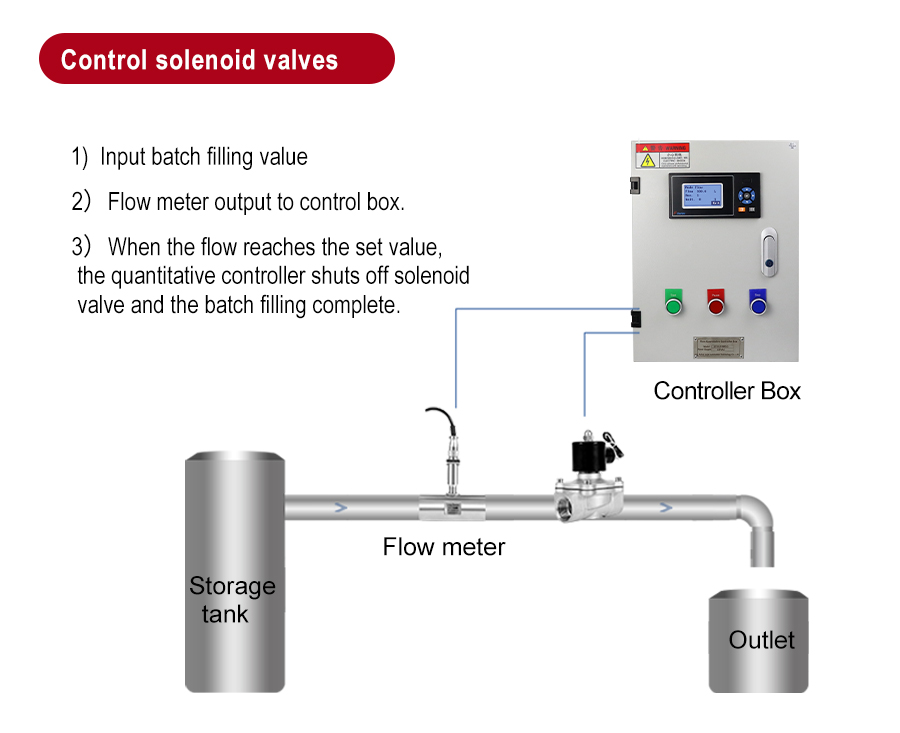

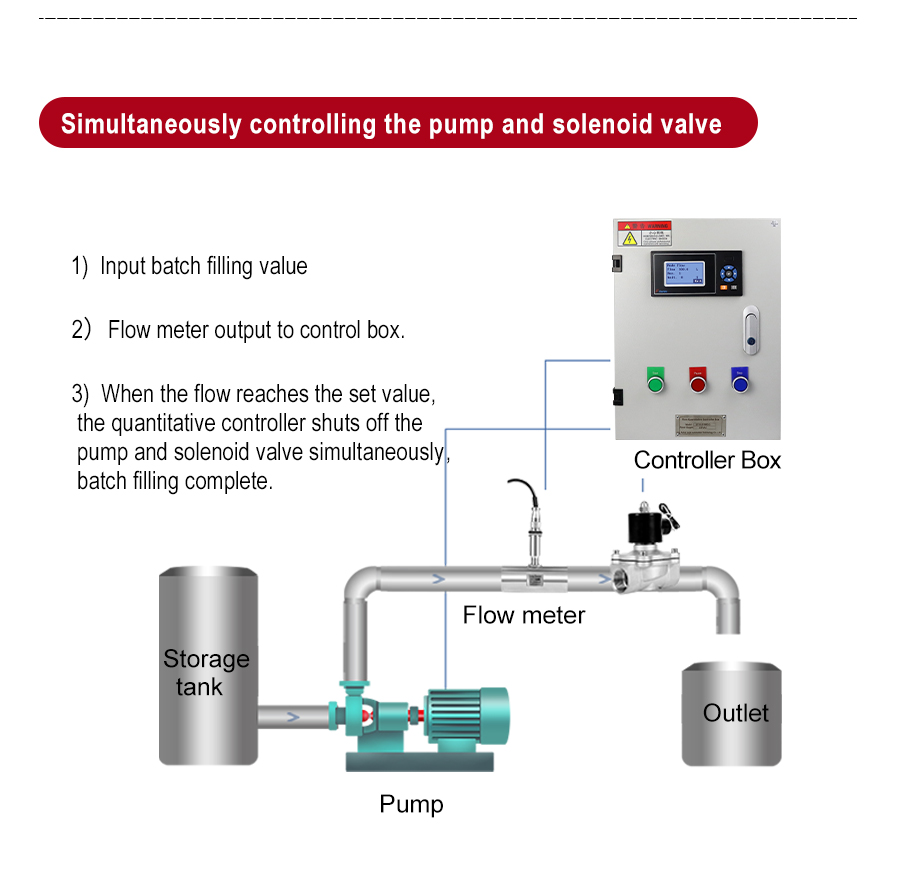

The core of the flow quantitative control box is the ARM microprocessor, and its measurement and control system is composed of various flow transmitters, sensors (such as turbine, vortex, electromagnetic, and other flowmeters), solenoid valve pump body, etc., which can integrate flow and carry out quantitative control. The man-machine interface and soft and hard protection measures of the flow quantitative control box are excellent. It has simple control operation, high safety performance, good disturbance immunity performance, and stability performance. Flow quantitative control box is applicable for chemical, petroleum, food, medicine, and other industries.

Characteristics

● Accurate measurement

● Convenient and simple operation

● One click start and stop

● Rapid quantification

● Suitable for a variety of occasions

Description

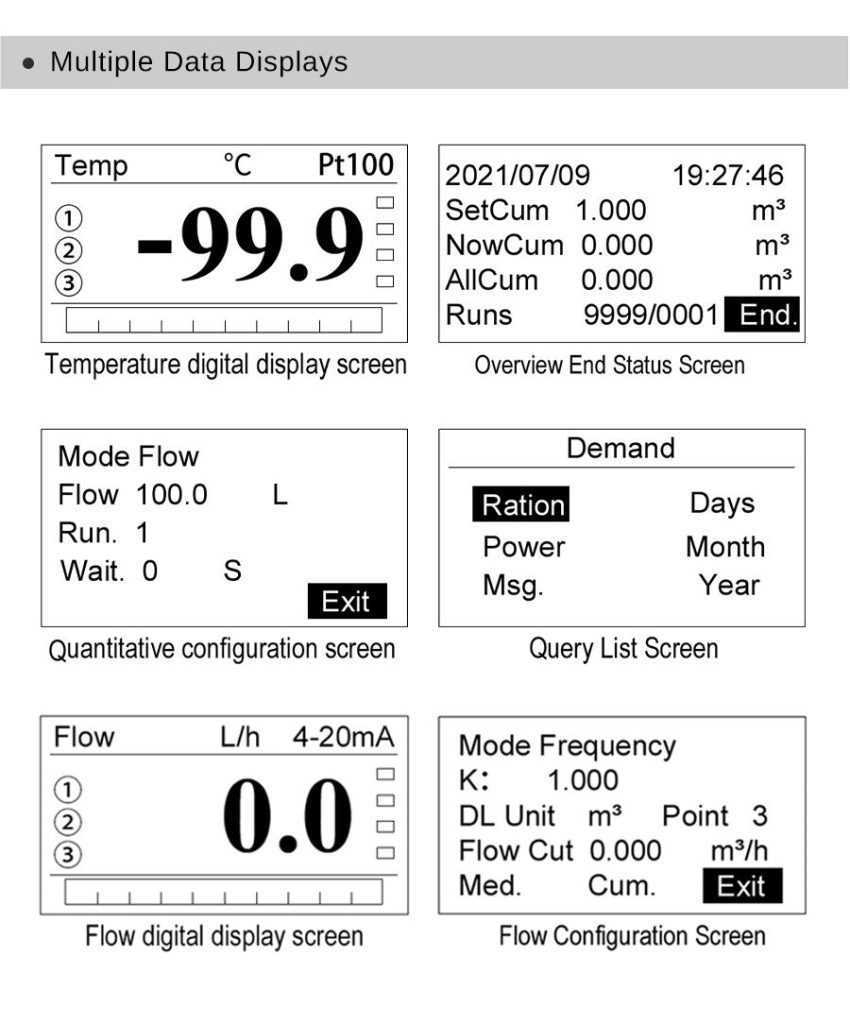

● Suitable for all kinds of liquid media flow display, control, integration functions, , which is widely used in the occasions of quantitative packaging and control, such as quantitative beating/feeding, batching, loading, distributing, aerating and discharging

● Input a variety of flow sensor signals (such as turbine, vortex, electromagnetic, elliptical gear, double rotor, mass flow and other flow meters)

● Communication Function: standard Modbus RTU protocol, support RS232C, RS485 communication interface

● Automatic conversion of flow unit, automatic calculation of flow coefficient of differential pressure flowmeter

● Call Function: support regular usage quick call

● Audit Records: outage records and quantitative records

● Cumulative Report: query the daily, monthly, and annual cumulative traffic reports

● Transmission Function: support standard current transmission output, signal source channel is optional

● Feed Function: support multiple specifications feed output to supply power to the sensor

● Protection Function: built-in memory to protect parameters and historical data, permanently save after power failure; Integrated hardware clock for accurate operation after power failure

● Flow Input Channel: receive frequency signals and a variety of analog current signals

● Temperature Input Channel: accept various analog current signals

● Provide transmitter +24V DC,+12V DC power supply, with short circuit protection function, simplify the system, reduce investment outlay

● Fault Tolerance Function: when the temperature/density compensation measurement signal is abnormal, the corresponding manual setting value is used to compensate the calculation

● Flow re-transmission function, output flow current signal, update cycle 1 second, to meet the needs of automatic control

● Instrument clock and timing automatic meter reading function, printing function, to make measurement management convenient

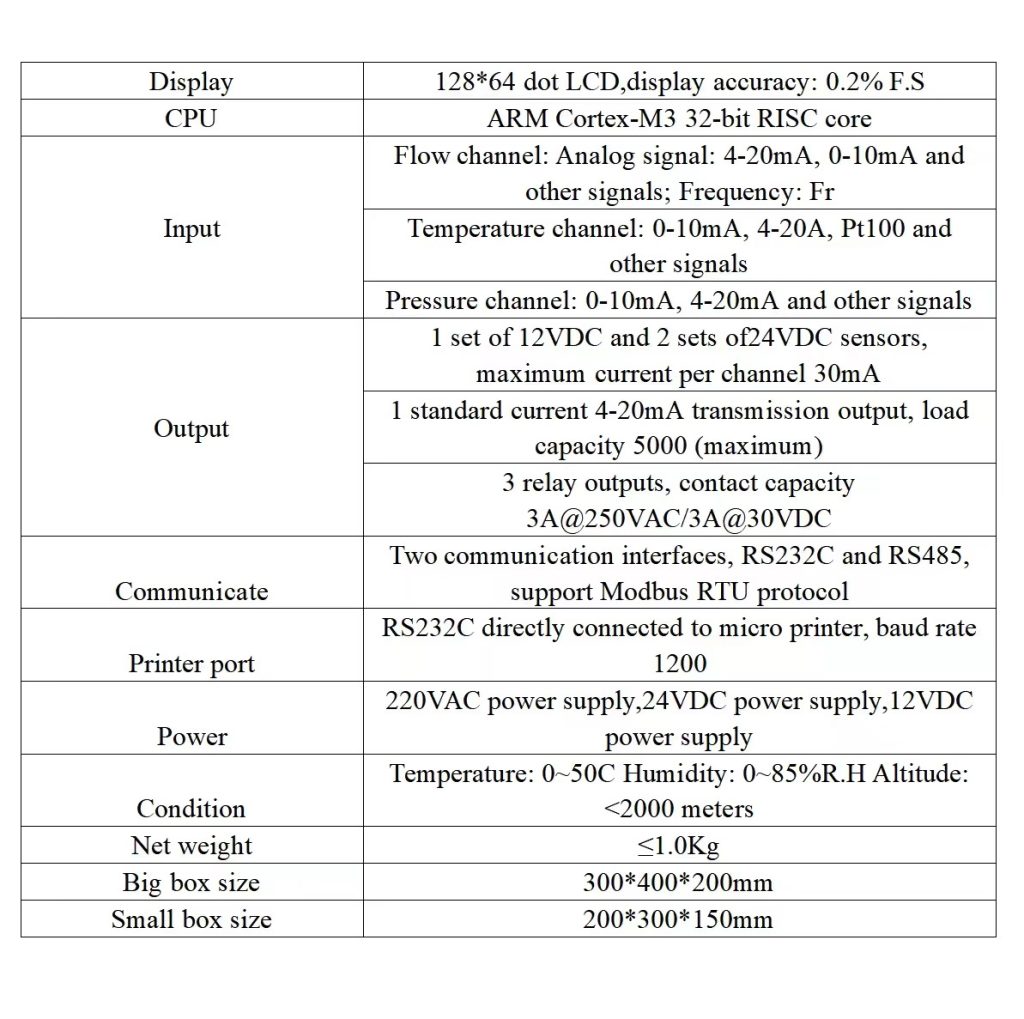

Product Parameters

Inquiry:

Please Feel Free To Leave Your Needs Here, A Competitive Quotation Will Be Provided According To Your Requirement.