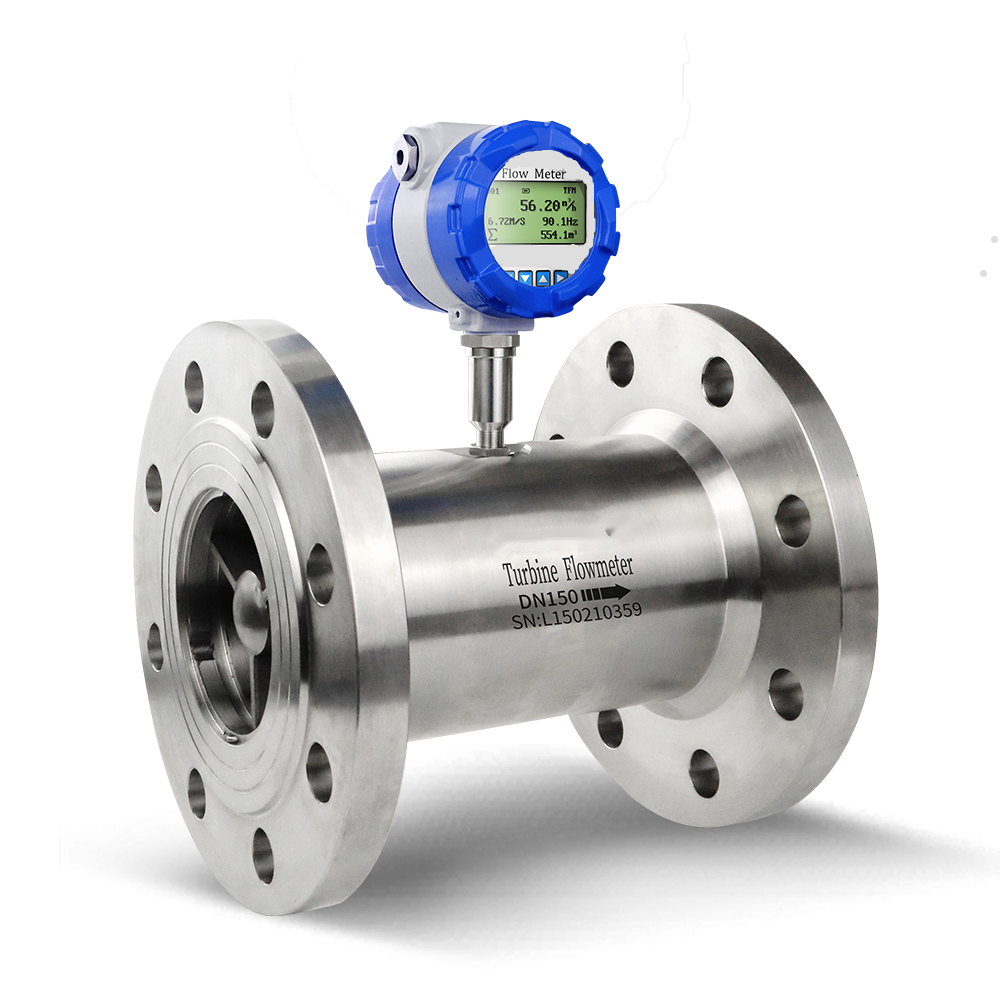

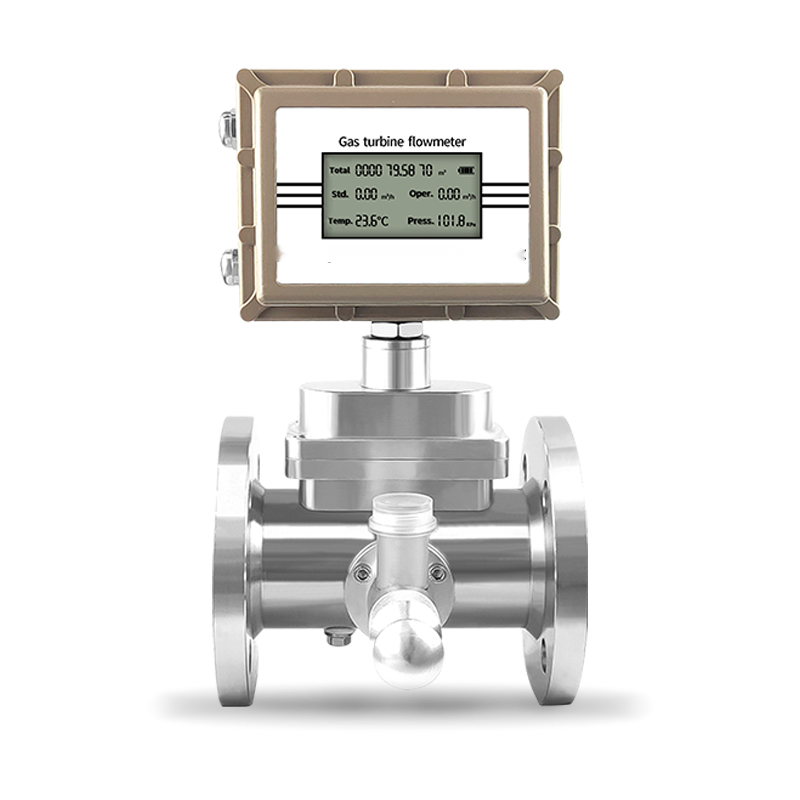

Turbine Flow Meter

The GTLWGY series turbine flow sensor is based on the torque balance principle and belongs to the speed flowmeter. The sensor has the advantages of simple structure, energy saving, high precision, lightweight, good repeatability, sensitive response, easy installation, maintenance, and use. Widely used in chemical, petroleum, water supply, metallurgy, paper, and other industries. It is suitable for measuring stainless steel 1Cr18Ni9Ti, corundum AI203, 2Cr13, cemented carbide, and other non-fiber, non-corrosive, particles and other impurities of the liquid. If it is equipped with a display instrument with special functions, it can be quantitative control and over-alarm. The explosion-proof version of this product (ExdIICT6 Gb) is suitable for an explosion-hazard environment. The sensor is applicable for medium with a viscosity less than 5×10-6m²/S at operating temperature, and for liquids with a viscosity greater than 5×10-6m²/S, after carrying out solid-liquid calibration, it can be used.

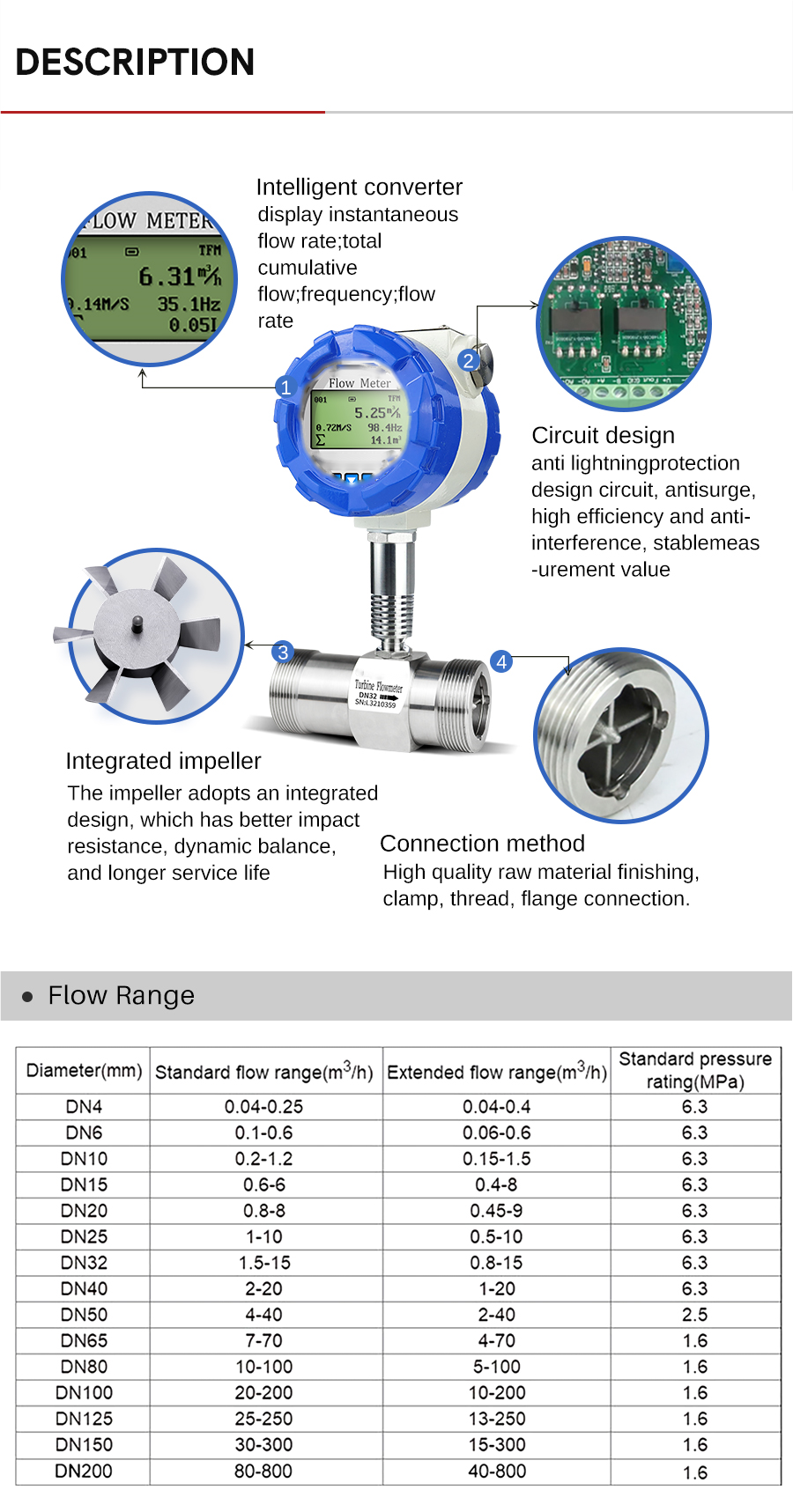

Characteristics

● The measurement of clean liquid

● Multiple connection methods

● One click start and stop

● Various calibers (DN4-DN200)

● Pulse, 4-20mA, RS 485 output

● Measurement accuracy level 0.5, level 1

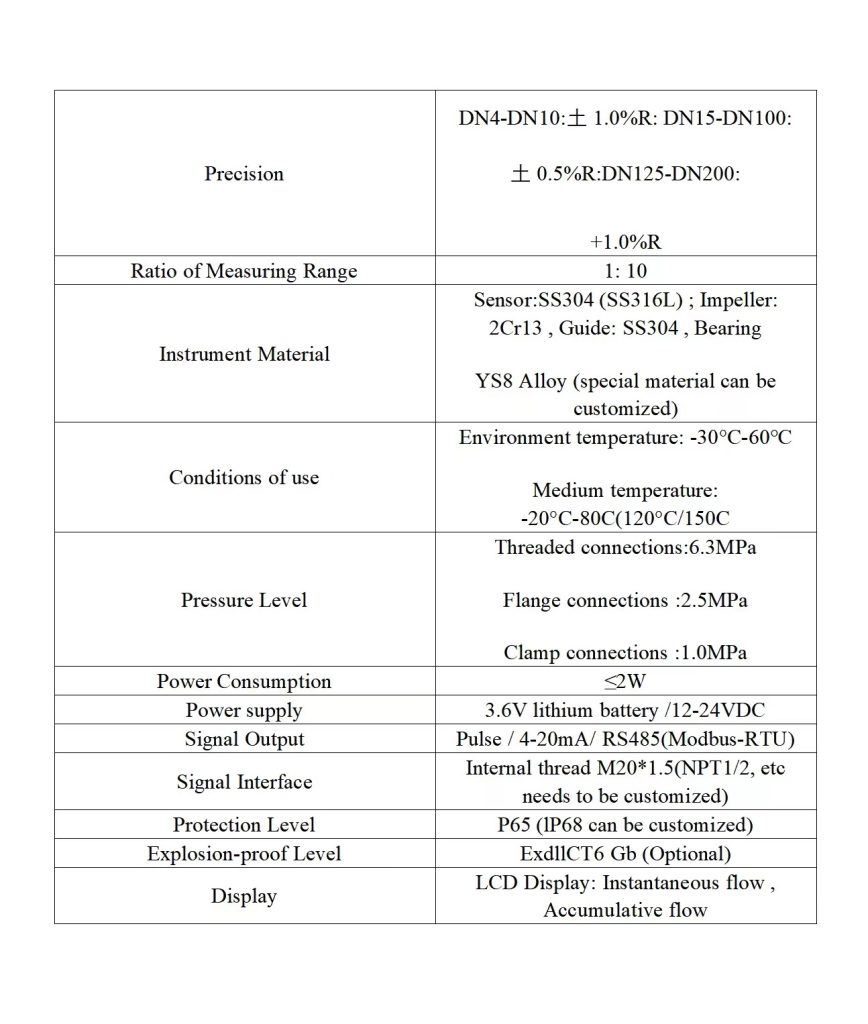

Specification

When the measured liquid flows through the sensor, under the action of the fluid, the impeller is forced to rotate, and its speed is proportional to the average flow rate of the pipeline. The rotation period of the impeller changes the magnetic resistance value of the magnetic circuit, and the magnetic flux in the detection coil changes periodically, resulting in an induced electromotive force whose frequency is the same as the rotation frequency of the blade. The practical flow equation of the turbine flowmeter is as follows:

Qv=f/K

Qv ……… The volume flow rate, m³/s;

f……… Frequency of flowmeter output signal, Hz;

K……… Meter coefficient of the flow meter, i/m³;

The instrument coefficient is divided into two sections, namely the linear section and the nonlinear section. The linear segment is about two-thirds of its working segment, and its characteristics are related to the size of the sensor structure and the fluid viscosity. The characteristics of nonlinear sections are greatly affected by bearing friction and fluid viscous resistance. When the flow rate is lower than the lower limit of the sensor flow, the instrument coefficient changes rapidly with the flow rate, and attention should be paid to prevent cavitation when the flow rate exceeds the upper limit.

Product Parameters

Inquiry:

Please Feel Free To Leave Your Needs Here, A Competitive Quotation Will Be Provided According To Your Requirement.